When you think about the tools that shape our world, the lathe often comes to mind, a machine that spins material to allow for precise cutting, sanding, or drilling. These machines are quite central to making so many things we use every day. Among the various types of these turning machines, the "russian lathe" has, you know, kind of a special place in many workshops and factories across the globe. It's a piece of equipment that often carries with it stories of durability and a certain way of doing things, reflecting, in a way, the vast and rich land it comes from.

This particular kind of machine, the Russian lathe, really does stand out for a few good reasons. It's not just another piece of metalworking equipment; it often represents a particular approach to engineering, one that values strength and a straightforward, no-fuss design. People who work with these machines sometimes talk about their solid build, their ability to handle tough jobs, and how they just keep going, year after year. It’s almost like they were made for the long haul, built to withstand a lot of use, which is pretty much what you want in a workshop.

So, as we talk about these fascinating machines, it helps to remember where they originate. Russia, the country, is, as a matter of fact, the largest on Earth, stretching across a huge part of Eastern Europe and North Asia. This vastness, with its many different regions and climates, has, you know, certainly played a part in shaping the kind of industrial tools that have come out of it. The machines, like the people and the land, often show a spirit of resilience and practicality, which is definitely something to appreciate when you're looking for reliable equipment.

Table of Contents

- What is a Russian Lathe?

- Where do these machines come from?

- Are Russian Lathes built to last?

- What makes a Russian Lathe unique?

- The Russian Lathe's Place in Workshops

- Caring for a Russian Lathe

- Understanding the Russian Lathe's Heritage

- A look at the Russian Lathe's Design Principles

What is a Russian Lathe?

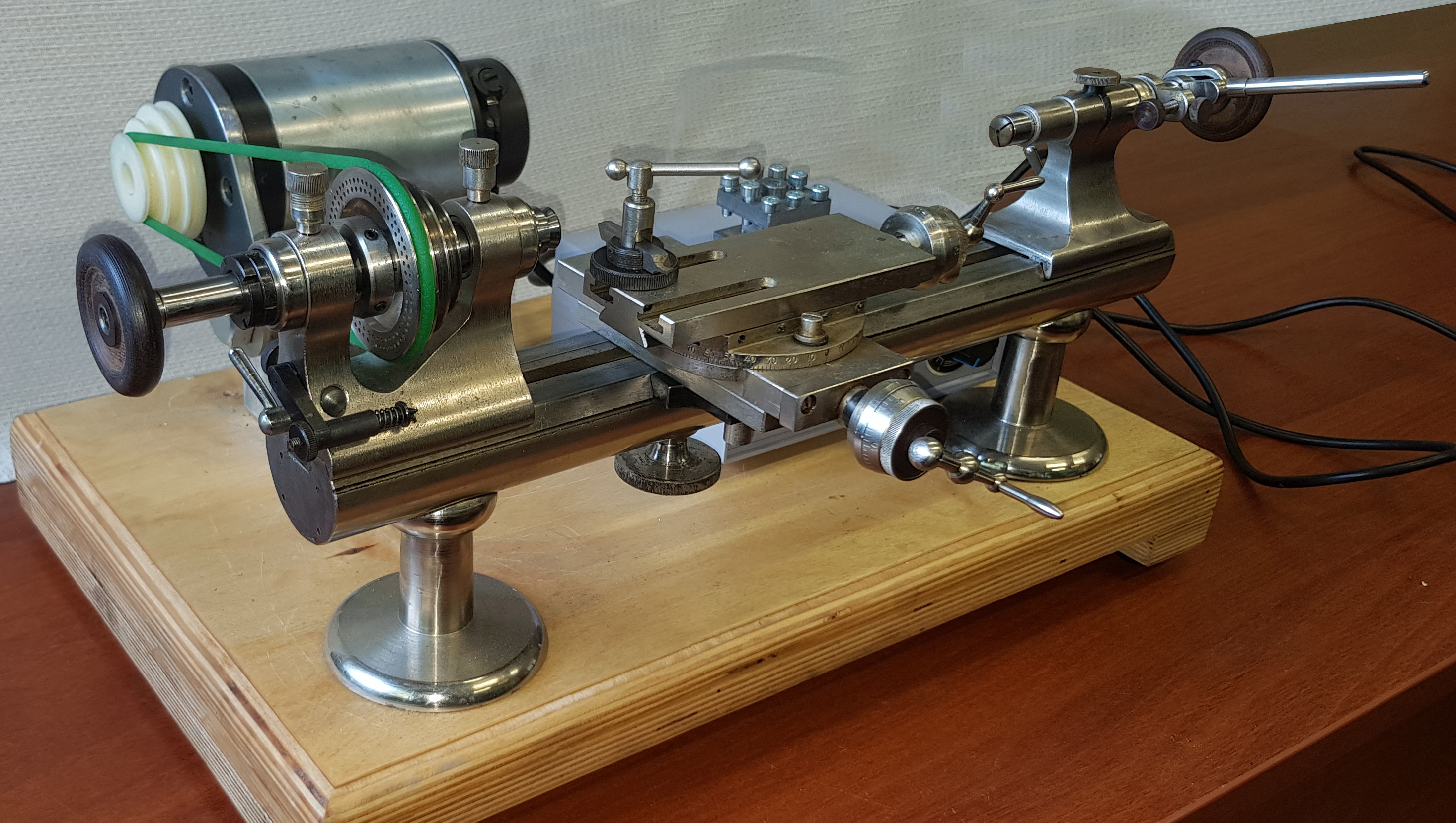

A Russian lathe, at its heart, is a machine tool that spins a piece of material, often metal or wood, so that another tool can shape it. Think of it like a potter's wheel, but for making precise parts. These machines are used to create cylindrical forms, to drill holes straight through the middle of something, or to smooth surfaces. They are a staple in many manufacturing settings, from small repair shops to big industrial sites. You know, they are pretty much essential for making so many things that need a round shape or a very straight hole.

When people talk about a "Russian lathe," they are usually referring to a machine manufactured in Russia or, in some cases, in countries that were once part of the Soviet Union. These machines often share certain design philosophies. They tend to be, you know, rather heavy and built with a lot of cast iron, which gives them a good deal of stability and helps to reduce vibrations during operation. This solid construction is something that many users really appreciate, as it contributes to the accuracy of the work you can do with them. It's almost like they are over-engineered in a good way, just to be sure they can handle whatever is thrown at them.

So, these machines are, basically, workhorses. They might not always have the flashiest features or the most intricate digital controls compared to some newer models from other parts of the world, but they make up for it with sheer dependability. They are often chosen for tasks where raw power and consistent performance are more important than, say, a super-sleek interface. This makes them, in a way, quite popular among those who value a tool that just gets the job done, day in and day out, without much fuss. They are, you know, pretty much what you'd call a reliable friend in the workshop.

Where do these machines come from?

These turning machines, known as Russian lathes, obviously come from Russia, a country that, as we mentioned, is really quite big. It stretches across a vast area, from the eastern parts of Europe all the way into North Asia. This immense size means that there are many different industrial centers spread out across its land, each potentially contributing to the making of these machines. It’s a place that has, you know, a very long history of heavy industry, especially going back to the days of the Union of Soviet Socialist Republics, or the U.S.S.R., where manufacturing was a very central part of the economy.

The sheer scale of Russia, which spans across eleven time zones, means that the industrial capacity for making things like these lathes is distributed over a truly huge landmass. From the Baltic Sea in the west to the Bering Strait in the east, you can find places where these machines were, and sometimes still are, produced. This wide distribution, you know, kind of speaks to the country's past efforts to build up its own manufacturing capabilities across its many regions. It wasn't just one factory; it was a whole network of places making these important tools.

The language spoken in Russia, Russian, is part of the East Slavic group of languages, and it's the native tongue for about 150 million people, with many more using it as a second language. This linguistic and cultural background, you know, subtly influences the design and the way things are made. There's a practical, straightforward approach that seems to be, in a way, woven into the fabric of their engineering. So, when you see a Russian lathe, you're not just seeing a machine; you're seeing something that reflects the industrial heritage and the very character of a truly expansive nation.

Are Russian Lathes built to last?

One of the most common things you hear about Russian lathes is their reputation for being incredibly tough and durable. People often say they are built like tanks, and in many ways, that's a pretty good description. They are typically made with a lot of heavy cast iron, which gives them a very solid foundation. This kind of construction, you know, really helps them to absorb vibrations and maintain accuracy, even when they are doing some very demanding work. It’s like they were designed to just keep going, no matter what.

The design philosophy behind many of these machines seems to prioritize longevity and the ability to withstand harsh conditions. They are often quite simple in their mechanical workings, which means there are fewer complex parts that could, you know, potentially break down. This straightforward design, combined with robust materials, contributes to their long operational life. You often hear stories of these lathes being used for decades, sometimes even passing down through generations of machinists, still performing well.

So, if you are looking for a machine that can take a beating and continue to perform reliably, a Russian lathe might be, in a way, a very good choice. Their build quality means they can handle heavy cuts and continuous use without showing much wear and tear. This focus on enduring performance, rather than on, say, fancy digital displays or automated features, really makes them stand out for their sheer staying power. They are, you know, basically designed to be truly dependable workhorses in any shop that needs a machine that can just keep on working.

What makes a Russian Lathe unique?

What really sets a Russian lathe apart often comes down to its core design principles. Unlike some machines that might prioritize speed or a very high degree of automation, Russian lathes often lean towards brute strength and mechanical simplicity. They are, you know, built with heavy-duty components that are meant to last, sometimes almost to an extreme degree. This means thicker castings, larger gears, and generally more substantial parts throughout the machine. It's a bit like comparing a very sturdy, old-school truck to a sleek, modern sports car; both get you there, but in very different ways.

Another unique aspect is their focus on manual operation and direct control. While modern lathes often feature computer numerical control (CNC) systems, many Russian lathes, especially older models, are purely manual. This means the operator has, you know, very direct control over every movement and cut. For skilled machinists, this can be a real advantage, allowing for a very hands-on approach to shaping materials. It also means less reliance on complex electronics that can, you know, sometimes be difficult to repair or replace.

Their reputation for being "overbuilt" is also quite unique. This isn't just about being heavy; it's about the generous sizing of key components like the spindle bearings, the bed ways, and the tailstock. These parts are often, you know, much larger than you might find on comparable machines from other countries, which contributes significantly to their stability and their ability to handle very demanding tasks without flexing or vibrating. So, in a way, their uniqueness lies in their dedication to pure, unadulterated mechanical strength and a straightforward, no-nonsense approach to metalworking.

The Russian Lathe's Place in Workshops

In many workshops around the world, particularly those dealing with heavy-duty fabrication, repair, or general machining, the Russian lathe has, you know, found a very comfortable home. These machines are often the go-to choice for tasks that require a lot of material removal or for working with very large or tough workpieces. Their solid construction means they can take on jobs that might cause smaller, lighter machines to struggle or even break down. They are, basically, the workhorses that get the really tough jobs done.

You'll often see these lathes in places where reliability is absolutely key and where continuous operation is expected. Think about a busy manufacturing plant, a facility that repairs large industrial equipment, or even, you know, a vocational school where students are learning the fundamentals of machining. In these environments, the ability of a Russian lathe to just keep working, day after day, without much fuss, is incredibly valuable. They might not be the fastest or the most automated, but their sheer dependability makes them, in a way, indispensable.

For many machinists, owning or working with a Russian lathe is almost like having a trusted old friend in the shop. They might require a bit more manual effort, but they offer a level of control and a feeling of solidness that some modern machines just don't provide. So, their place in workshops is really as a symbol of enduring quality and a straightforward approach to metalworking, a machine that, you know, you can always count on to perform its task with a lot of grit and determination.

Caring for a Russian Lathe

Caring for a Russian lathe is, in some respects, pretty similar to looking after any other piece of heavy machinery, but there are a few things that, you know, might be worth noting given their particular characteristics. Because they are often built with such robust, heavy components, they tend to be quite forgiving when it comes to minor neglect, but consistent care will, of course, ensure they last even longer. It’s like with any sturdy tool; a little bit of attention goes a very long way.

Regular lubrication is, basically, very important. These machines have many moving parts, gears, and slides that need a steady supply of oil to reduce friction and prevent wear. Following the manufacturer's lubrication schedule, or establishing your own if the original isn't available, is a good idea. Keeping the ways and other critical surfaces clean and free of chips and debris is also, you know, essential. Swarf and dust can cause premature wear if not regularly removed, so a quick wipe-down after each use is a pretty good habit to get into.

Because of their simple, mechanical nature, repairs on many Russian lathes can often be done without needing highly specialized electronic diagnostic tools. Many parts are, you know, quite substantial and can sometimes be repaired or even fabricated if a replacement isn't readily available. This makes them, in a way, quite practical for workshops that prefer to do their own maintenance. So, with a bit of regular care and attention to the basics, a Russian lathe can, quite literally, serve you well for a very, very long time, which is, you know, a great thing for any workshop.

Understanding the Russian Lathe's Heritage

To truly appreciate the Russian lathe, it helps to understand a bit about its background and the country it comes from. Russia, as we know, is a really vast country, stretching from Eastern Europe into North Asia. This immense geographical spread, combined with a history of significant industrial development, particularly during the Soviet era, has, you know, greatly influenced the engineering and manufacturing traditions there. The focus was often on producing large quantities of durable, functional machinery to support a growing industrial base.

During the time of the Soviet Union, there was a strong emphasis on self-sufficiency and robust production. This meant that machines like lathes were designed to be reliable, easy to maintain, and capable of operating in a wide range of conditions, from the colder northern parts to the more temperate southern regions. The design philosophy often prioritized strength and straightforward mechanics over, say, elaborate aesthetics or overly complex systems. This heritage is, in a way, pretty evident in the machines themselves, which often feel very solid and purposeful.

The Russian language, which is spoken by about 260 million people and is one of the four East Slavic languages, also, you know, plays a part in this heritage. The terminology used in their technical manuals and the way engineers communicate often reflects a very direct and practical approach. This cultural emphasis on practicality and durability is, basically, woven into the very fabric of the machines. So, when you operate a Russian lathe, you are, in a way, connecting with a long line of industrial innovation that valued resilience and dependable performance above all else.

A look at the Russian Lathe's Design Principles

When you take a closer look at the design principles behind a Russian lathe, you start to see a consistent pattern emerge: a dedication to mechanical integrity and a preference for straightforward solutions. These machines are often built with very substantial castings for the bed and headstock, which, you know, provides a very rigid foundation. This rigidity is incredibly important for maintaining accuracy during cutting operations, especially when dealing with tough materials or heavy workpieces. It's almost like they were designed to be unshakable.

The gearing and power transmission systems in many Russian lathes are also typically very robust. They often use large, hardened gears that are designed to withstand significant torque and continuous use without wearing out quickly. This emphasis on durable internal components means that the machine can deliver consistent power to the cutting tool, even under demanding loads. You know, it's pretty much about ensuring that the machine can handle whatever task is thrown at it without faltering.

Furthermore, the controls on these lathes are often quite intuitive and mechanically driven, rather than relying heavily on electronics. This can be a real benefit in workshops where simplicity of operation and ease of repair are valued. The overall design ethos seems to be, in a way, about creating a machine that is reliable, easy to understand, and capable of a long working life with minimal fuss. So, the design principles of the Russian lathe really do reflect a commitment to building a machine that is, basically, a true workhorse, built for endurance and dependable performance.

The Russian lathe, with its origins in a vast and industrially rich country, represents a particular approach to machine building. These machines are known for their strong, durable construction, often featuring heavy cast iron and robust mechanical components. They are typically seen as reliable workhorses in workshops, valued for their ability to handle demanding tasks and their longevity. Their design often emphasizes manual control and straightforward mechanics, reflecting a heritage of practical engineering. Caring for them involves regular lubrication and cleaning, and their simple construction often makes maintenance quite manageable. Understanding their background, rooted in Russia's expansive geography and industrial past, helps to appreciate why these lathes are built to last and perform consistently.

Detail Author:

- Name : Orlo Weimann

- Username : adan12

- Email : stefanie.wintheiser@kovacek.org

- Birthdate : 1978-01-21

- Address : 60727 Brianne Glen Suite 162 Homenickstad, NJ 80836

- Phone : (341) 239-0947

- Company : Brekke and Sons

- Job : Agricultural Equipment Operator

- Bio : Qui repellat recusandae ullam dolores autem veritatis ducimus et. Enim temporibus unde assumenda maxime. Aliquid accusantium et ea veritatis nisi.

Socials

linkedin:

- url : https://linkedin.com/in/jessie_green

- username : jessie_green

- bio : Laudantium esse et aut nemo.

- followers : 6697

- following : 2002

instagram:

- url : https://instagram.com/jessiegreen

- username : jessiegreen

- bio : Enim at aut modi vel vel. Facere unde debitis excepturi magni autem natus. Laborum ipsum et nemo.

- followers : 4864

- following : 2034

tiktok:

- url : https://tiktok.com/@jessie_green

- username : jessie_green

- bio : Cupiditate at aspernatur quam itaque voluptas.

- followers : 5961

- following : 121